1

Receiving Material

- Quality control

- Raw Material inspection

2

Raw Material Storage

- Room temp.

- Cooling Room (Temp and % Humidity control)

- First In First Out Control

3

Weighing prepare Raw Material

- Control Equipment before/after use.

- Program control barcode system

- Control temp and % humidity Storage. (after open bag)

- Control 5S before/after use.

4

Recheck Raw material

- Recheck kind and weigh of raw material 100% before mixing (Barcode system)

- Control temp and % humidity Storage.

5

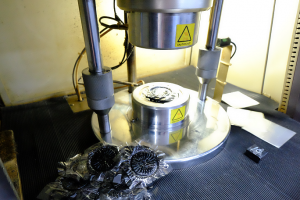

Mixing (Keader)

- Control condition standard mixing.

- Check contaminate of machine before/afer mixing.

- Control temp and % humidity mixing.

- Control mixing chart.

- Temperature control by Chiller machine.

6

Mixing (Two Roll Mill)

- Control condition standard mixing.

- Check contaminate of machine before/afer mixing.

- Control temp and % humidity mixing.

- Temperature control by Chiller machine.

- Controlled tapping by Cross Roll Blender machine.

7

Cooling

- Control temp and % humidity mixing.

- Check contaminate of machine before/afer.

8

Cutting

- Control temp and % humidity mixing.

- Check contaminate of machine before/afer.

- Check contaminate by Metal Detector.

9

Packing

- Control temp and % humidity mixing.

- Check contaminate of machine before/afer.

- Contaminate Check.

10

Packing in cotton box

- Control temp and % humidity mixing.

- Contaminate Check.

11

Quality control

- Check properties of FKM Compound.

- COA.

12

Delivery to Customer

- Storage control temp and % humidity before delivery.

- FIFO Control.